I. Introduction

Power tool batteries play a crucial role in the efficiency and performance of power technology tools across various industries. As technology advances, the demand for more powerful, longer-lasting, and environmentally friendly batteries continues to grow.

The significance of battery technology , delves into their historical development, and introduces the next-generation innovations shaping the industry. If you’re wondering where to recycle power tool batteries, you can find more information and resources at housebouse.com.

A. Brief History Of Power Tool Technology

The evolution of power tool batteries traces back several decades, marked by significant technological advancements aimed at enhancing performance and usability. The earliest iterations of power tool batteries relied on traditional nickel-cadmium (NiCd) technology, which although revolutionary at the time, posed environmental concerns due to the presence of toxic cadmium.

As environmental awareness grew and regulations tightened, manufacturers turned to nickel-metal hydride (NiMH) batteries as a more eco-friendly alternative. NiMH batteries offered higher energy densities and eliminated the use of cadmium, addressing environmental concerns while delivering improved performance and longevity.

B. Introduction To Next-Generation Power Tool Batteries

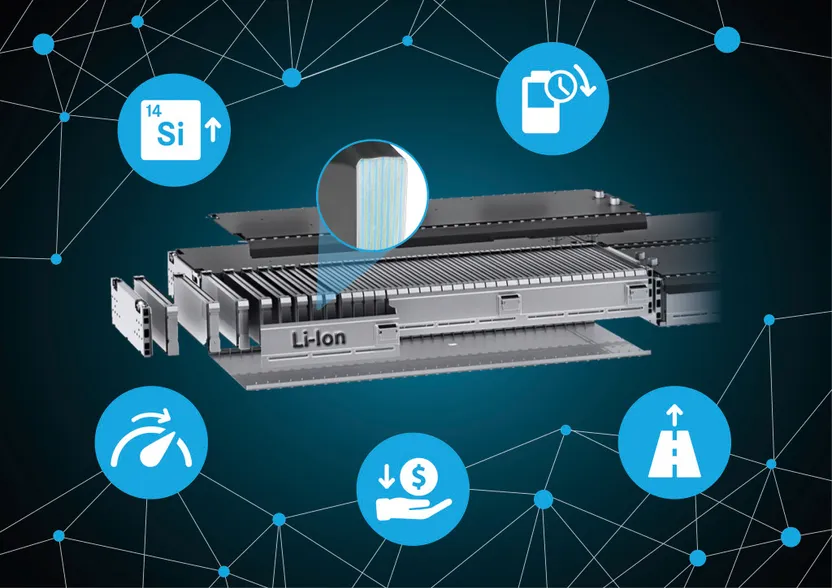

In recent years, lithium-ion (Li-ion) batteries have emerged as the next frontier in power tool technology, revolutionizing the industry with their unparalleled performance and versatility. Li-ion batteries boast higher energy densities, lighter weights, and reduced self-discharge rates compared to their predecessors, making them ideal for powering modern power tools.

One of the most significant advantages of Li-ion batteries is their ability to maintain a consistent voltage throughout the discharge cycle, ensuring consistent power delivery until depletion. This characteristic translates to sustained performance and enhanced productivity, allowing users to complete tasks without the downtime associated with voltage drops.

Moreover, Li-ion batteries are renowned for their fast-charging capabilities, enabling users to recharge their power tools quickly and get back to work with minimal interruption. This feature is particularly beneficial in high-demand environments where time is of the essence, allowing professionals to maximize their efficiency and meet tight deadlines.

II. The Evolution Of Power Tool Battery Technology

Power tool batteries have undergone a remarkable evolution over the years, driven by the need for more efficient, longer-lasting, and environmentally friendly solutions. This evolution can be categorized into three main stages, each marked by significant advancements in power tool technology.

A. Traditional Nickel-Cadmium (Nicd) Batteries

The journey of power tool batteries began with the introduction of nickel-cadmium (NiCd) batteries. These batteries, which emerged in the mid-20th century, represented a groundbreaking innovation in portable power sources. NiCd batteries were lauded for their ability to deliver consistent power output and withstand high discharge rates, making them ideal for powering early generations of cordless power tools.

However, despite their technological advancements, NiCd batteries came with their drawbacks. One of the most significant issues was the environmental impact of cadmium, a toxic heavy metal used in their construction. Cadmium posed serious health and environmental risks, leading to stringent regulations and a push for more eco-friendly alternatives.

B. Advancements With Nickel-Metal Hydride (Nimh) Batteries

In response to growing environmental concerns, manufacturers turned to nickel-metal hydride (NiMH) batteries as a more sustainable alternative to NiCd batteries. NiMH batteries replaced cadmium with a hydrogen-absorbing alloy, significantly reducing their environmental footprint while maintaining comparable performance levels.

NiMH batteries offered several advantages over their predecessors, including higher energy densities, lower self-discharge rates, and improved cycle life. These advancements made NiMH batteries well-suited for a wide range of applications, including power tools, consumer electronics, and electric vehicles.

Despite their improvements, NiMH batteries still had limitations, including relatively lower energy densities compared to emerging technologies and a tendency to experience voltage drops as they approached depletion.

C. Introduction Of Lithium-Ion (Li-Ion) Batteries

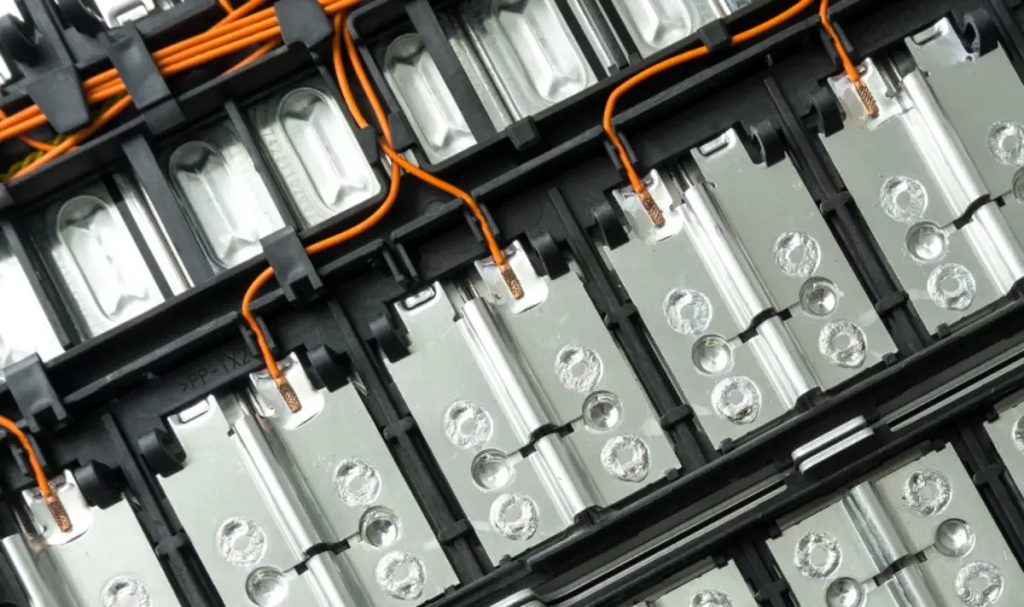

The introduction of lithium-ion (Li-ion) batteries heralded a new era in power tool technology, revolutionizing the industry with their superior performance and versatility. Li-ion batteries leverage lithium ions as the primary charge carriers, offering higher energy densities, lighter weights, and longer cycle life compared to NiCd and NiMH batteries.

One of the most significant advantages of Li-ion batteries is their ability to maintain a consistent voltage throughout the discharge cycle, ensuring uninterrupted power delivery until depletion. This characteristic eliminates the voltage drops associated with NiCd and NiMH batteries, providing users with a more consistent and reliable power source.

Moreover, Li-ion batteries boast faster charging capabilities, allowing users to recharge their power tools in a fraction of the time compared to traditional battery technologies. This feature is particularly advantageous in fast-paced environments where downtime is minimized, and productivity is maximized.

III. Innovations Driving Next-Generation Batteries

The landscape of power tool batteries is continually evolving, driven by groundbreaking innovations aimed at pushing the boundaries of performance, efficiency, and sustainability. In recent years, several key advancements have emerged, shaping the next generation of power tool batteries.

A. Nanotechnology Advancements

Nanotechnology has emerged as a game-changer in the development of next-generation power tool batteries. By manipulating materials at the nanoscale level, researchers have unlocked new possibilities for improving battery performance and energy storage capacity.

One notable application of nanotechnology in battery design involves the use of nanostructured materials, such as nanowires and nanoparticles, to enhance electrode surface area and facilitate faster ion transport. This results in batteries with higher energy densities, faster charging rates, and improved cycle life, making them ideal for demanding applications in power tools.

Furthermore, nanocoatings have been developed to enhance the stability and longevity of battery components, reducing degradation and prolonging battery lifespan. These advancements in nanotechnology promise to revolutionize the capabilities of next-generation power tool batteries, enabling users to tackle tasks with unprecedented efficiency and reliability.

B. Solid-State Batteries

Solid-state batteries represent another groundbreaking innovation poised to reshape the power tool industry. Unlike traditional lithium-ion batteries, which use liquid electrolytes, solid-state batteries utilize solid electrolytes, offering several key advantages.

One of the most significant benefits of solid-state batteries is their enhanced safety and stability. By eliminating flammable liquid electrolytes, solid-state batteries are inherently less prone to thermal runaway and other safety hazards, making them ideal for high-demand applications such as power tools.

Additionally, solid-state batteries exhibit higher energy densities and longer cycle life compared to their liquid electrolyte counterparts. This translates to longer runtimes and reduced maintenance requirements, allowing users to operate their power tools with confidence and peace of mind.

While solid-state batteries are still in the early stages of commercialization, ongoing research and development efforts are rapidly advancing this technology, paving the way for widespread adoption in the power tool industry.

IV. Conclusion

Next-generation power tool batteries represent a significant leap forward in power technology, offering unparalleled performance, efficiency, and reliability. Advancements in battery technology have revolutionized the power tool industry, enabling professionals and enthusiasts to tackle tasks with greater ease and precision. Their high-quality batteries provide extended run times, faster charging, and increased durability for an efficient and enjoyable power tool experience.

Frequently Asked Questions (FAQ)

Q: What are next-generation power tool batteries?

Next-generation power tool batteries refer to advanced battery technologies designed to enhance the performance, runtime, and safety of power tools. These batteries typically incorporate innovations like nanotechnology, solid-state designs, and smart features to improve efficiency and user experience.

Q: How do next-generation batteries differ from traditional ones?

Unlike traditional batteries such as nickel-cadmium or nickel-metal hydride, next-generation batteries, often lithium-ion based, offer longer runtime, faster charging, and increased durability. They also tend to be lighter and more environmentally friendly due to their reduced use of toxic materials.

Q: What benefits do next-generation power tool batteries offer?

Next-generation batteries provide several advantages, including extended runtime, enhanced performance, faster charging times, improved safety features, and reduced environmental impact. These benefits translate to increased productivity, less downtime, and greater convenience for users.

Q: Are next-generation batteries compatible with existing power tools?

Compatibility may vary depending on the specific battery and tool models. While some next-generation batteries are designed to be compatible with existing power tool platforms, others may require adapters or modifications. It’s essential to check compatibility before purchasing or upgrading batteries.

Q: What are the key innovations driving next-generation technology?

Innovations such as nanotechnology, solid-state designs, and smart features play significant roles in advancing next-generation battery technology. Nanotechnology allows for higher energy densities and faster charging rates, while solid-state designs improve safety and longevity. Smart features, including battery management systems, enable better performance monitoring and optimization.